Paulk Miter Stand Pdf Viewer

Paulk Miter Stand Pdf To Excel. Woodworker's Journal - Ultimate Miter Saw Stand Plan. For all sorts of cross- and angle- cutting tasks, a miter saw is a woodworker's friend. But, to really maximize its potential, you need a good home base for your saw - and that's what this project delivers. The stand is a full 8 ft. Package # 4 contains the Paulk Total Station, Miter Stand and Cross Cut Jig Plans. PDF plans for the Paulk Workbench II This is our most popular plan. The Paulk Homes Store. Package # 4 contains the Paulk Total Station, Miter Stand and Cross Cut Jig Plans. The Paulk Miter Stand Plans d elivered via PDF.

Chris, Very Nice! Ten years ago, I built a miter saw station similar but smaller. We were building a giant hotel, which I won’t mention the name. On my station, I had two drawers and an open cabinet to keep hand and power tools in. I rolled that saw station from one end of that building to the other. Antony Johnsons Crying Light Zip Hoodies. Bottom floor to the top.

We had to carry it up and down the stairs because elevators weren’t installed yet. After seeing your miter saw station, I would like to build a newer, updated one. Can you send me the plans for your project. Download Normativa Uni En 12845 Pdf Free. Thanks, Greg B •.

Great chop saw station. I am a subscriber to your magazine and enjoy reading it. I would like the PDF file if it not too inconvenient for you. Just a note, if you want a true precision measuring system that is repeatable to 0.001″, then buy an Incra Fence System.

I install an 4′ Incra Fence on my Dewalt Mitrie station and It is great. If you forget to cut a board to a certain length, you don’t have to worry about getting the same exact length again. Since with an Incra fence system is repeatable to 0. Glovepie Wiimote Mouse Script. 001″. Again, great chop/mitrie saw station.

Hi Chris, I built this in 2011 for a gentleman. I used Birch plywood for the construction with Birch trim and edges as needed. I did use Poplar for the drawer assemblies and when finished it gave a nice contrast. I modified the saw area at the rear wall as he wanted to use a DeWalt 12″ sliding miter saw with slides that hit when rotating it side to side. Other than that the plans were excellent, I did change up the scrap drawers a little. He said he didn’t know if he could make himself us it because it might scratch it!

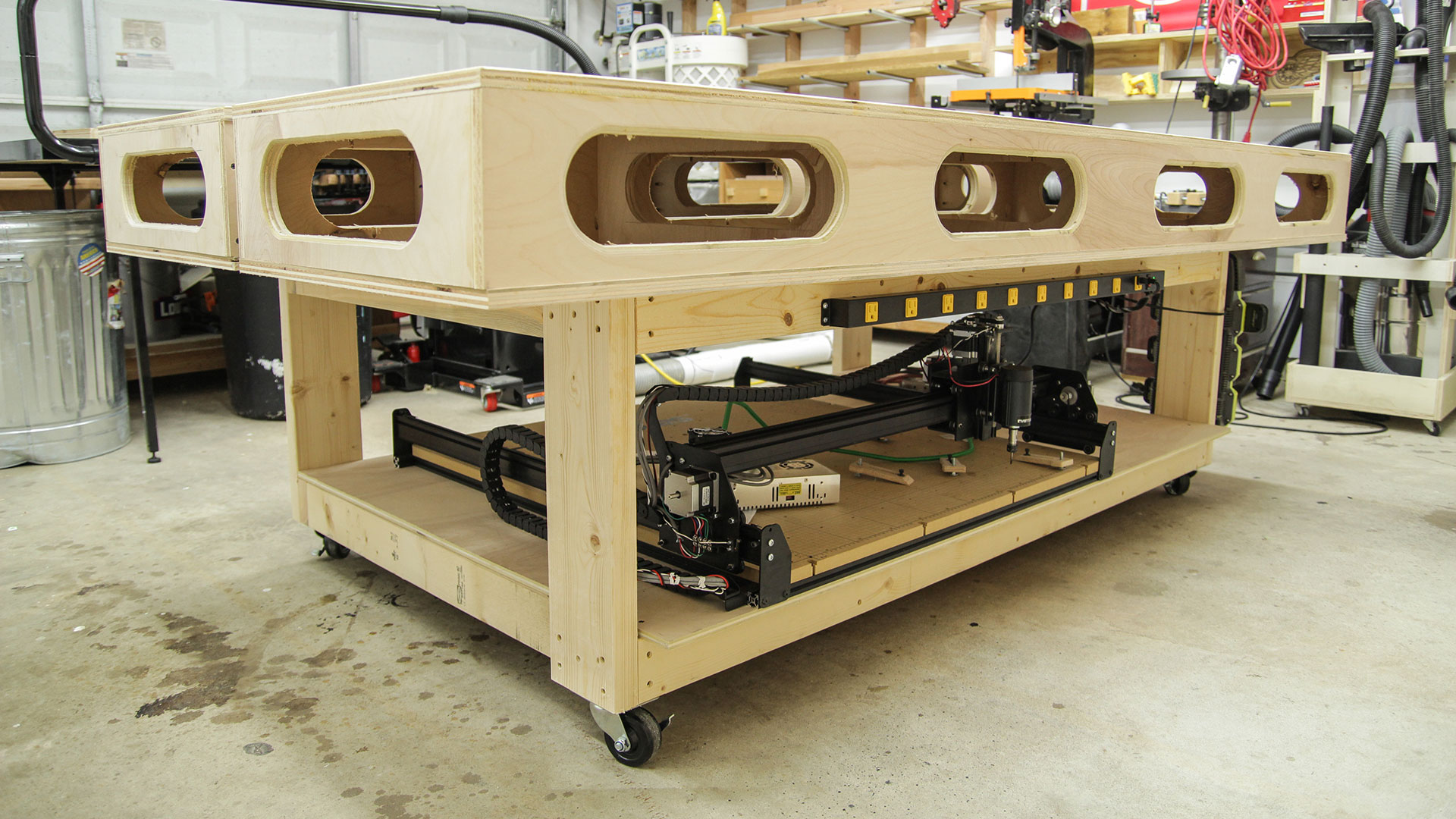

Ultimate: Last in a train of progression or consequences; tended toward by all that precedes; arrived at, as the last result; final. I have been designing and building homes for a while, and, somehow, I completed all of them without the aid of the Ultimate Work Bench (UWB), but I always knew there had to be a better way. What Makes a Work Bench Ultimate? Usually, when the finish work begins, saw horses come out, plied with door blanks—one, two, sometimes even three.

One for a table saw out-feed, and one or two others for assemblies. Trying to put mantels together on these small surfaces was just too difficult, which meant that large projects ended up on the floor—ugh, my back, my knees! The same was true for wainscot, which I like to pre-assemble with pocket screws and a few dominoes. Then there are cabinets and book cases.

While most cabinets show up ready to install, it seems I’m always fabricating a bookcase or two. And then there’s always that little niche which just demands some custom work. (Note: Click any image to enlarge) So the quest began. I wanted a large, waist-high surface that could handle bigger projects. I also wanted somewhere to store tools. These days, I have specialty tools for everything. Routers (not just a router), track saw (how did I ever complete a project without one of those?); pocket hole cutter, drills, screw guns, mallet, chisels, and the Festool Domino (the coolest tool ever), tape measure, and the various accessories which inevitably come along for the ride.

If I put the tools on the work bench, then there is no space for the work piece. If I put the tools on the floor, then my back and knees suffer.

If putting the tools on the top is no good, and the floor is even worse, what do I do? And how do I clamp wood or jigs to the bench? I know this much: a table saw out-feed is a must in my workflow. Lastly, how do I get the work bench from job to job?

It can’t be too big or too heavy to handle solo. So there it is: I want a bench with a large surface, tool storage, clamping options, table saw out-feed, and it has to be light enough for one person to manage. I’ll make it big and small, heavy and light, plus fold-able to carry it around in my back pocket! Well, the last part might be going too far, but what about the rest? After figuring out the properties of the ultimate work bench, it was time to design it, which is where the fun begins—in the virtual wood shop.